About Rolling Bearings

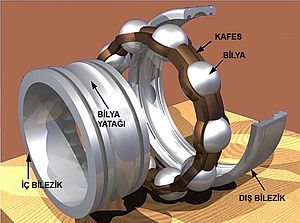

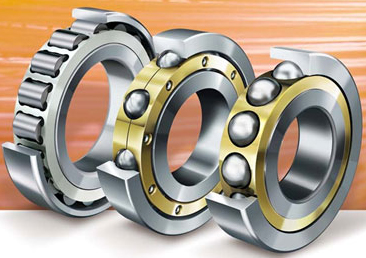

Rolling bearings generally comprise two bearing rings with integral raceways.

Rolling elements are arranged between the rings and roll on the raceways. For particular applications, rolling bearings with a full complement of balls, cylindrical rollers or needle rollers may be used.

Rolling elements movement in raceways.

Rolling elements can be balls, cylindrical rollers, needle rollers, tapered rollers or barrel rollers. The rolling elements are generally guided by a cage that keeps them at a uniform distance from each other and prevents them coming into contact with each other.

Rolling elements can be balls, cylindrical rollers, needle rollers, tapered rollers or barrel rollers. The rolling elements are generally guided by a cage that keeps them at a uniform distance from each other and prevents them coming into contact with each other.

Every rolling bearing design has characteristic features that make it especially suitable for specific bearing applications. It is not possible to draw up generally valid rules for the selection of the bearing type as several factors usually have to be considered and weighed up such as:

Bearing type selection factors:

* Radial load

* Axial load

* Rotation Speed

* Working time and periods

* Life expectancy

* Bearing arrangements

* Installation space

* Lubrication method

* Sealing elements

* Operating temperature

* Expected sound level

* Expected vibration level

* Radial space available

* Axial space available

Please click here for online Bearing Selection Guide.